CPVC Pipes & Fittings

Highlight of the Products

- Ideal for hot and cold water applications

- Suitable for water temperature upto 93°C

- Wide range of pipes and fittings from 1⁄2″ to 6″ (15 mm to 150 mm)

- Pipes & Fittings upto 2"(50 mm) can withstand 28.1kg/cm2 pressure at 27°C and 6.93kg/cm2 at 82°C

- Safe for potable water

- UV Stabilised

- No bacterial growth

- Ease of installation

- Designed for over 50 years life

- Pipes upto 2″ (50 mm) are manufactured as per IS:15778:2007 and fittings as per ASTM 2846 standards

- Pipes above 2″ (50 mm) are manufactured as per ASTMF 441 & Fittings as per ASTMF 438 & 439

CPVC Pipes - Product Availability,

Pressure Rating And Standards

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM3 | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 27°C | 82°C | ||

| SDR 11 | 12” to 2” (15 mm to 50 mm) | IS:15778:2007 | ASTM D 2846 | 28.1 | 6.93 |

| SDR 13.5 | 1⁄2” to 2” (15 mm to 50 mm) | IS:15778:2007 | - | 22.23 | 5.61 |

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM3 | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 23°C | 82°C | ||

| SCH 40 | 2 1⁄2” (65 mm) | ASTM F 441 | ASTM F 438 | 21.09 | 5.27 |

| SCH 40 | 3” (80 mm) | ASTM F 441 | ASTM F 438 | 18.28 | 4.57 |

| SCH 40 | 4” (100 mm) | ASTM F 441 | ASTM F 438 | 15.47 | 3.87 |

| SCH 40 | 6” (150 mm) | ASTM F 441 | ASTM F 438 | 12.66 | 3.16 |

| SCH 80 | 2 1⁄2” (65 mm) | ASTM F 441 | ASTM F 439 | 29.53 | 7.38 |

| SCH 80 | 3” (80 mm) | ASTM F 441 | ASTM F 439 | 26.01 | 6.33 |

| SCH 80 | 4” (100 mm) | ASTM F 441 | ASTM F 439 | 22.49 | 5.62 |

| SCH 80 | 6” (150 mm) | ASTM F 441 | ASTM F 439 | 19.69 | 4.92 |

CPVC Is Resistant To Water Temperature

- 93°C for SHORT term application

- 82°C for CONTINUOUS application. It keeps hot water hotter and cold water colder as compared to GI and copper plumbing

| TEMPERATURE DE-RATING FACTOR FOR CPVC | |

|---|---|

| WORKING TEMPERATURE | DE-RATING FACTOR |

| °C | |

| 23-27 | 1.00 |

| 32 | 0.91 |

| 38 | 0.82 |

| 49 | 0.65 |

| 60 | 0.50 |

| 71 | 0.44 |

| 82 | 0.25 |

| 93 | 0.20 |

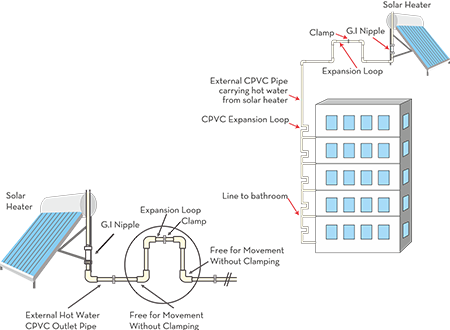

Installation ProCedure

A. Guidelines

- Connect minimum 1 mtr. Length of metal pipe to the outlet of hot water tank.

- Ventilation-proper air-venting on the hot water outlet side is a must.

- Use of expansion loop is highly recommended to avoid snaking effect caused due to expansion & contraction of pipe.

- Although CPVC has the lowest thermal conductivity amongst all alternate plastic plumbing systems, however to maintain thermal efficiency, it is recommended that the pipes should be insulated. PE foam may be used over the pipe to provide adequate insulation.

B. Horizontal and vertical spacing for pipe supporting(clamping of pipes)

| NOMINAL PIPE DIA | SPACING | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| INCH | MM | 20°C | 50°C | 70°C | 80°C | ||||

| FT | MTR | FT | MTR | FT | MTR | FT | MTR | ||

| 1⁄2" (15 mm) | 12.00 | 5.50 | 1.70 | 4.50 | 1.40 | 3.00 | 0.90 | 2.50 | 0.80 |

| 3⁄4" (20 mm) | 19.00 | 5.50 | 1.70 | 5.00 | 1.50 | 3.00 | 0.90 | 2.50 | 0.80 |

| 1" (25 mm) | 25.00 | 6.00 | 1.80 | 5.50 | 1.70 | 3.50 | 1.10 | 3.00 | 0.90 |

| 1 1⁄4" (32 mm) | 32.00 | 6.50 | 2.00 | 6.00 | 1.80 | 3.50 | 1.10 | 3.00 | 0.90 |

| 1 1⁄2" (40 mm) | 40.00 | 7.00 | 2.10 | 6.00 | 2.00 | 3.50 | 1.10 | 3.50 | 1.10 |

| 2" (50 mm) | 50.00 | 7.00 | 2.10 | 6.50 | 2.00 | 4.00 | 1.20 | 3.50 | 1.10 |

| 2 1⁄2" (65 mm) | 65.00 | 8.00 | 2.40 | 7.50 | 2.30 | 4.50 | 1.40 | 4.00 | 1.20 |

| 3" (80 mm) | 80.00 | 8.00 | 2.40 | 7.50 | 2.30 | 4.50 | 1.40 | 4.00 | 1.20 |

| 4" (100 mm) | 100.00 | 9.00 | 2.70 | 8.50 | 2.60 | 4.50 | 1.40 | 4.50 | 1.40 |

| 6" (150 mm) | 150.00 | 10.00 | 3.00 | 9.00 | 2.70 | 5.50 | 1.70 | 5.50 | 1.50 |

Do not clamp supports tightly, it restricts the movement of pipe caused because of expansion and contraction.

Installation with solvent cement

CUTTING

De-Burring

Cleaning/Dry

Solvent Cementing

Assembly

Solvent Cemented Jointing

- Dry fitment-check joint of pipe to fitting without solvent cement, should fit up to 60 – 70%

- Cold fusion joint (cold welded joint)

- For diameters 1⁄2" to 2”, single step solvent cement

- For diameters 21⁄2” to 4”, 2 step solvent cement (primer + solvent cement)

- Primer helps to clean the surface of pipe & fitting and softens the material

| AVERAGE INITIAL SET SCHEDULE FOR CPVC SOLVENT CEMENT | |||

|---|---|---|---|

| TEMP RANGE | PIPE SIZE 1⁄2” – 11⁄4” | PIPE SIZE 11⁄2” – 3” | PIPE SIZE 31⁄2” – 4” |

| 16° - 38°C | 2 minutes | 5 minutes | 30 minutes |

| 5° - 16°C | 5 minutes | 10 minutes | 2 hours |

| -18° - -5°C | 10 minutes | 15 minutes | 12 hours |

Note - Typical set schedule is required time before it is advisable to carefully handle joint. In wet or humid conditions, additional set time maybe required of up to 50% of amount listed. Use as general guidelines only.

- Cure time-Curing time is longer than the set time. Curing means the joint has completely matured

- The pressure test can only be performed after the joint is completely cured

| AVERAGE JOINT CURE SCHEDULE FOR CPVC SOLVENT CEMENT | ||||||

|---|---|---|---|---|---|---|

| RELATIVE HUMIDITY60% OR LESS | PIPE ∅ 1⁄2” – 11⁄4” | PIPE ∅ 11⁄2” – 2” | PIPE ∅ 21⁄2” – 4” | |||

| TEMP. RANGES DURING ASSEMBLY & CURE PERIODS | BAR | BAR | BAR | |||

| UP TO 11 | 11 TO 26 | UP TO 11 | 11 TO 22 | UP TO 11 | 11 TO 22 | |

| 16° - 38°C | 15 min | 6 hrs | 30 min | 12 hrs | 1 1⁄2 hrs | 24 hrs |

| 5° - 16°C | 10 min | 12 hrs | 45 min | 24 hrs | 4 hrs | 48 hrs |

| -18° - -5°C | 15 min | 48 hrs | 1 hr | 96 hrs | 72 hrs | 8 days |

Note - Joint cure schedule is the necessary time to allow before pressurizing system. In damp or humid weather allow 50% more cure time.

In case of using paint on CPVC piping system, use only Latex based paints which are water based to make it workable and brushable. No Oil/Solvent based paints are to be used as these paints can drastically reduce the life of the systems.

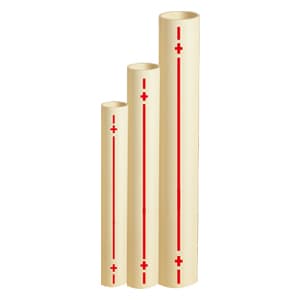

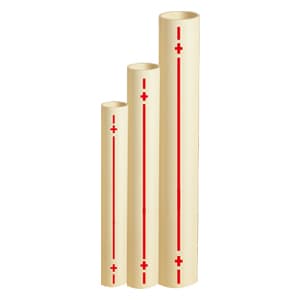

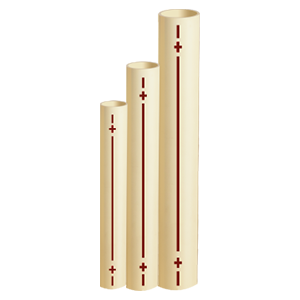

| Type of PIPE | Colour | Image |

|---|---|---|

| SDR 11 | Red strip |  |

| SDR 13.5 | Brown strip | |

| SCH 40 | Brown strip | |

| SCH 80 | Red strip |

CPVC plumbing system for hot & cold water

CPVC Pipes - HSN Code 3917

SDR 11/SDR 13.5 Pipes Manufactured as per is15778:2007

SDR-11 (3Mtr. Length)

SDR-11 (5Mtr. Length)

SDR-13.5 (3Mtr. Length)

SDR-13.5 (5Mtr. Length)

SDR-11 (6 Mtr. Length)

CPVC Fittings

HSN CODE:3917

Fittings Manufactured as per ASTM D2846:2007

Coupler Plain

Bend 45° Plain

Tee 90° Plain

Elbow 90° Plain

Reducer Elbow 90°

Cross Tee 90°

Reducer MTA

Reducer Tee 90° Plain

Reducer Bush Plain

Female Adaptor Plastic Threaded (FAPT)

Male Adaptor Plastic Threaded (MAPT)

End Cap Plain

Union

Tank Nipple

Tank Nipple (With One Side Pipe Fitment)

Reducer

Step Over Bend

Transition Bushing (IPS X CTS)

Ball Valve

Long Bend

Threaded End Plug

Concealed Valves

Mixer Adaptor

CPVC Fittings

BRASS - HSN CODE:3917

Elbow 90°

Male Adaptor Brass Threaded (MABT)

Female Adaptor Brass Threaded (FABT)

Tee

Reducer MTA (Plastic Nut)

Reducer FTA

Reducer MTA – HEXA Nut

CPVC Fittings

COMMON

Plastic Clamps

Powder Coated Metal Clamps

CPVC Pipes

HSN CODE:3917

SCH 40/SCH 80 Pipes Manufactured as per ASTM F441: 2013

SCH-40 (3Mtr.Length)

SCH-40 (5Mtr.Length)

SCH-80 (3Mtr.Length)

SCH-80 (5Mtr.Length)

CPVC Fittings

SCH - 80 - HSN CODE:3917

SCH 80 Fittings Manufactured as per ASTM F439: 2013

Coupler Plain

Tee 90° Plain

Transition Bushing (IPS X CTS)

Elbow 90° Plain

Reducer Bush

CPVC Solvent Cement & Primer

HSN CODE:3506

Medium Duty Step 1 (Yellow)

Heavy Duty 2 Step (Orange)

Primer

Superior quality CPVC Pipes and Fittings from Truflo

Truflo Pipes, one of the leading CPVC pipe manufacturers in the market for CPVC pipes and fittings, ensures their CPVC (Chlorinated Polyvinyl Chloride) pipes and fittings are manufactured using the best material and technology, which makes them highly feasible for both hot as well as cold water distribution system. A Truflo CPVC pipe is produced by chlorination of the traditional PVC material, which adds to the CPVC pipes and fittings’ strength and enables the CPVC pipe to withstand high temperatures (up to 93°C). Temperatures over this may soften the material and weaken its joints. Also, our CPVC are versatile to fit a diverse range of applications.

Our CPVC pipes and fittings are fit for a variety of applications like agriculture systems, industrial pr°Cess lines, irrigation systems, swimming pools, water supply systems, and fire fighting systems etc. They are superior to Ductile pipes (D.I), Copper Iron(C.I), and Reinforced Cement Concrete (RCC) pipes and come with added benefits like lightweight, excellent corrosion, easy and fast installation, and chemical resistance, long life, high flow rates, and economical.

Our CPVC pipes, CPVC fittings, and CPVC pipes and fittings are the most viable option for hot and cold water distribution systems as our piping systems are approved and certified to carry potable water.

CPVC Pipes and Fittings for a wide range of applications

Being among the best CPVC pipe manufacturers, our CPVC pipes are produced in SDR and SCH series - SDR-11 (3 metres and 5 metres), SDR-13.5 (3 metres and 5 metres), SCH-40 (3 metres and 5metres), and SCH-80 (3 metres and 5 metres). They are made from identical CPVC compound material having the same physical properties. The CPVC fittings include coupler plain, elbow 90, bend 45, reducer elbow 90, tee 90, reducer tee 90 plain, cross tee 90, end cap plain, reducer bush plain, MAPT, FAPT, tank nipple, union, reducer, transition bushing, reducer MTA, step over bend, threaded end plug, and ball valve are all available in different sizes to fit your specific applications. The CPVC Brass Fittings include elbow 90 brass, tee brass, MABT, FABT, reducer MTA brass, and Reducer FTA brass of different sizes. All our CPVC pipes are produced in compliance with the set industry standards.

Along with being able to withstand high hot and cold temperatures, CPVC pipes and fittings are also self-extinguishing and hence, do not support combustion, have lower thermal conductivity, no bacterial growth compared to other Piping Material, and have resistance to UV.

FAQ’s

CPVC Pipes are categorized based on their Pressure ratings and Wall Thickness. CPVC Pipes are available in SDR 11 and 13.5 and SCH 40 & 80.

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM³ | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 27°C | 82°C | ||

| SDR 11 | 1⁄2” to 2” (15 mm to 50 mm) | IS:15778:2007 | ASTM D 2846 | 28.1 | 6.93 |

| SDR 13.5 | 1⁄2” to 2” (15 mm to 50 mm) | IS:15778:2007 | - | 22.23 | 5.61 |

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM³ | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 23°C | 82°C | ||

| SCH 40 | 2 1/2” (65 mm) | ASTM F 441 | ASTM F 438 | 21.09 | 5.27 |

| SCH 40 | 3” (80 mm) | ASTM F 441 | ASTM F 438 | 18.28 | 4.57 |

| SCH 40 | 4” (100 mm) | ASTM F 441 | ASTM F 438 | 15.47 | 3.87 |

| SCH 40 | 6” (150 mm) | ASTM F 441 | ASTM F 438 | 12.66 | 3.16 |

| SCH 80 | 2 1/2” (65 mm) | ASTM F 441 | ASTM F 439 | 29.53 | 7.38 |

| SCH 80 | 3” (80 mm) | ASTM F 441 | ASTM F 439 | 26.01 | 6.33 |

| SCH 80 | 4” (100 mm) | ASTM F 441 | ASTM F 439 | 22.49 | 5.62 |

| SCH 80 | 6” (150 mm) | ASTM F 441 | ASTM F 439 | 19.69 | 4.92 |